Classification of oil-free bearings

Oil-free bearings mainly include gas-lubricated bearings, composite lubricated bearings, water-lubricated bearings, etc.

1. Gas lubricated bearings:

Gas-lubricated bearings are plain bearings that use gas as lubricant. The most commonly used gas lubricant is air, but nitrogen, argon, hydrogen, helium or carbon dioxide can also be used as required. Gas-lubricated bearings form a load-bearing air film by the same mechanism as liquid-lubricated bearings. Gas-lubricated bearings take advantage of the transmission, diffusion, viscosity and thermal conductivity, adsorption and compressibility of gas. Under the action of hydrodynamic pressure effect, hydrostatic pressure effect and extrusion effect, a complete air film is formed between the friction pairs, which has the function of supporting the load and reducing friction.

Gas-lubricated bearings are generally divided into three types: gas-hydrodynamic bearings, gas-hydrostatic bearings and gas-extrusion bearings. The lubrication state of the actual bearing often exists in the form of dynamic and static pressure, dynamic and extruded, static and extruded and dynamic, static and extruded mixed lubrication states. Gas-lubricated bearings form a load-bearing air film by the same mechanism as liquid-lubricated bearings.

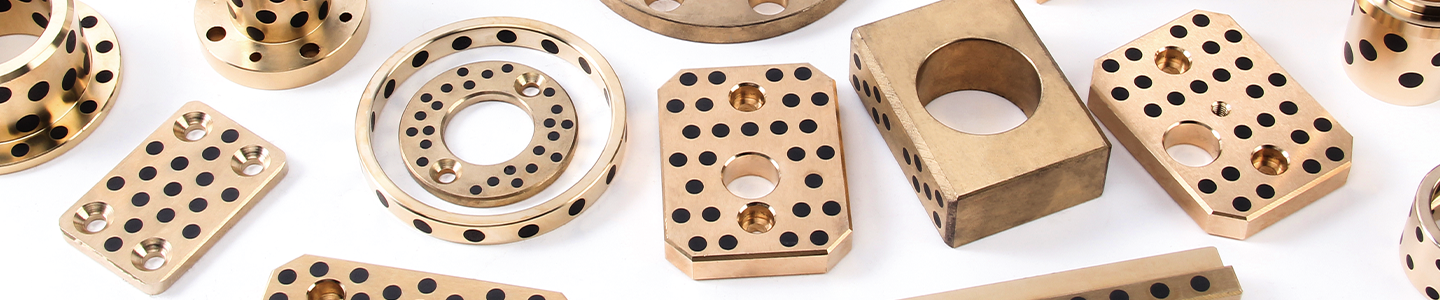

2. Composite lubricated bearings

Due to the requirements of special production processes, some key equipment of industrial and mining enterprises operate under extremely harsh working conditions. Due to the heavy equipment, high ambient temperature, large dust or acidic corrosive gas in the air, etc. The lubrication of the equipment has brought many problems, the friction and wear are serious, and most of the traditional oil and grease lubrication are still used, but in fact, these industrial and mining conditions have exceeded the scope of oil and grease lubrication. It is very easy to bite or bite the bearing and other friction pairs. Causes severe wear and damage to parts, often resulting in equipment downtime.

The composite material used in composite lubrication bearing is a new type of anti-extreme pressure solid lubricating material, which is composed of a metal substrate and a solid lubricant paste embedded in a hole or groove of the substrate. During friction, the metal substrate bears the bulk of the load. After friction, the solid lubricant in the hole or groove is transferred or reversed to the friction surface, and a well-lubricated, firmly adhered and evenly covered solid transfer film is formed on the friction surface, which greatly reduces friction and wear. As the friction progresses, the embedded solid lubricant is continuously supplied to the friction surface, ensuring good lubrication of the friction pair during long-term operation.

3. Water-lubricated bearings

Since the oil resource crisis in the 70s of the 20th century and people's attention to environmental protection in recent years, hydraulic transmission technology is facing severe challenges, and water-lubricated bearings have begun to be gradually popularized and applied. Water-lubricated bearings use water as the lubrication and working medium, which not only saves a lot of oil, but also avoids the environmental pollution of traditional bearings with oil as the lubricating medium. At the same time, water has the advantages of no pollution, wide range of sources, safety and flame retardancy, etc., and is an ideal lubricating medium. In addition, it can reduce the friction, wear, vibration, noise, non-functional consumption and other key problems of the friction pair. Therefore, the research of water-lubricated bearings has important theoretical research and application value for improving mechanical efficiency and protecting the environment, and has become a hot spot of concern in various countries.