- Home

- About

- Product

- Size

- Data

- The meaning of self-lubricating bearings

- PV Value Calculation for Bearings - Definition

- The maximum allowable PV value

- The design of the matching housing bore - straight sleeve bearing

- Matching housing bore design - flange bearing

- The design of the matching shaft

- Matching shaft surface roughness

- Matching shaft hardness

- Matching shaft surface treatment

- Mechanism design of matching shafts

- Factors that affect the life of the bearing

- The formula for calculating the press-in force F during assembly

- Straight sleeve assembly method

- Flanging assembly method

- Thrust gasket, plate assembly method

- Inspection method for the outer diameter of the rolled bearing

- Inspection method for the inner diameter of the rolled bearing

- Test method for thrust sheets

- Surface roughness comparison table

- Plain bearing technical parameters consultation form

- Application

Product Introduction

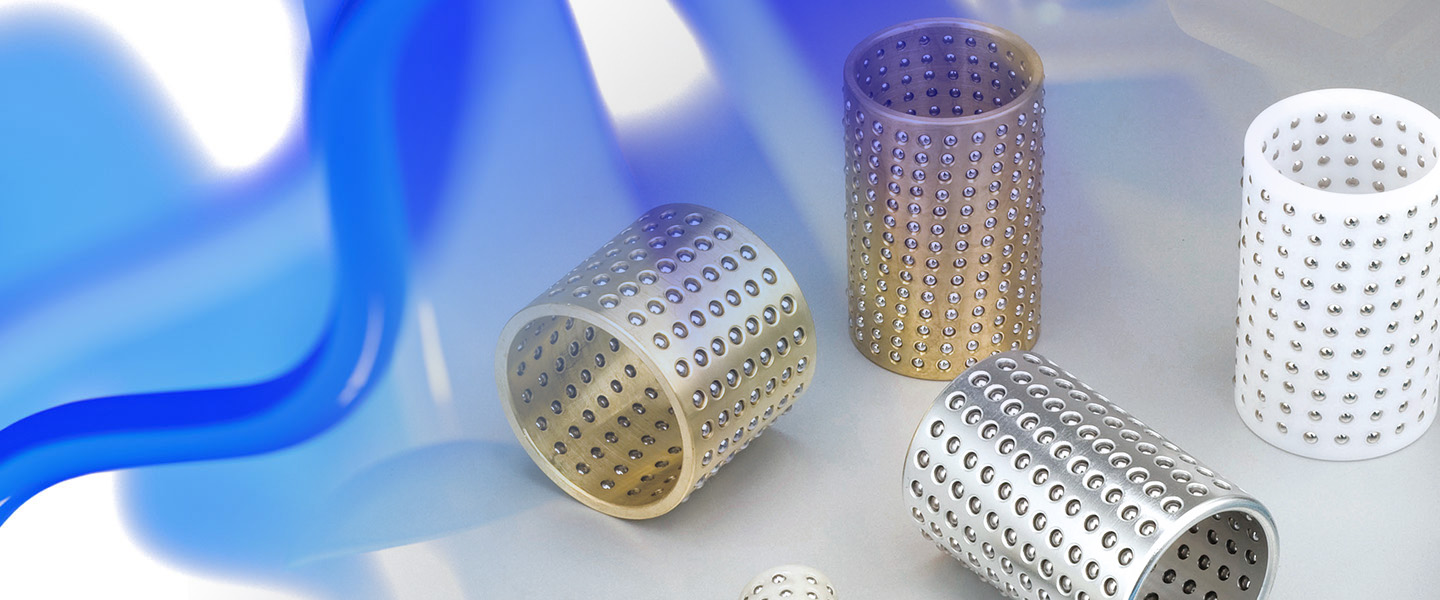

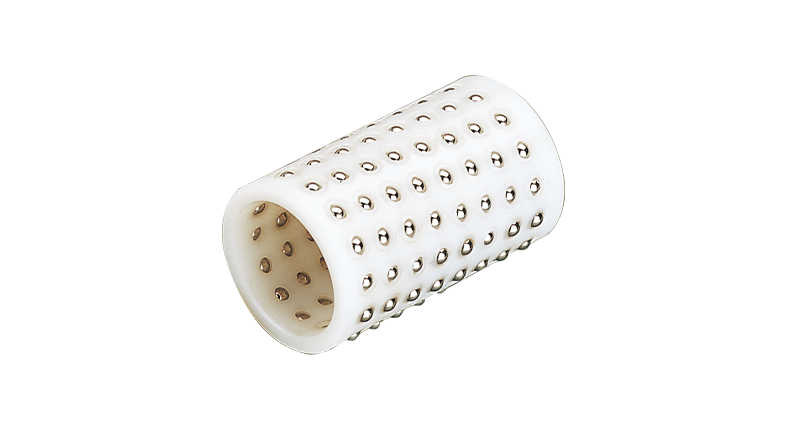

RBB (copper-based), RBA (aluminum-based) and RBS (resin-based) steel balls are kept solid, with copper alloy, duralumin alloy and POM resin as the matrix respectively, and on its outer surface, the holes arranged in an orderly manner, appropriate size and special shape are processed, and the rolling bearing steel balls are embedded in the holes. The mouth adopts the latest groove circumferential locking technology, which effectively solves the problem that the traditional locking ball and indentation locking ball cannot completely prevent the steel ball from falling off. The bottom of the hole is machined with a 90° stop, so that the steel ball rotates freely in the hole without falling off. Because the diameter of the steel ball is greater than the wall thickness of the retaining ring, the steel ball is higher than the inner and outer surface of the retaining ring when used, and is directly in contact with the matching hole and the shaft, so that the matrix (retaining ring) floats in the middle, and the difference between the radius of the matched hole and the shaft is less than the diameter of the steel ball, that is, the steel ball is matched with interference fit, the matching accuracy is high, and the relative motion of the shaft and the hole is flexible. It is a renewal product of the keepring.

Benefits & Uses:

The traditional hole with relative motion and the shaft have a certain gap, and the motion friction coefficient between the hole and the shaft is larger, after using the steel ball to keep the ring, the shaft and the hole are not in direct contact, but through the steel ball with a trace interference in the middle, thus the motion accuracy is high, the rolling friction replaces the dynamic friction, the rolling is flexible, the friction coefficient is small, the service life is long, in the occasion of both rotation and movement, the shaft sleeve without oil or oil is matched with the shaft, although it can be satisfied, but the motion accuracy is low, and the rolling bearing can only meet the occasion of the relative rotation of the shaft, The steel ball retaining ring, the above two conditions have been satisfied, has been widely used in cold stamping die rolling die base, high-precision machine tools, machine tool accessories and high-precision axial or axial radial simultaneous motion occasions.

Requirements for matching parts

1. Guide bushing: material GCrl5, YB9, heat treatment, hardness HRC62~66, technical conditions according to GB/T12446 and shaft should have 0.01-0.02 radial interference, surface roughness

1. Guide bushing: material GCrl5, YB9, heat treatment, hardness HRC62~66, technical conditions according to GB/T12446 and shaft should have 0.01-0.02 radial interference, surface roughness

3. Measurement: Use general measurement means (pneumatic measuring instrument, outer diameter dry scale, inner diameter dial gauge, etc.) to measure the dimensional deviation value of the shaft guide sleeve and the steel ball, and the interference after fitting can be found, that is, Ymax=dmax+2d'-DmIn, and the interference is required to be 0.01-0.02mm